Swarf Crusher KB20

Powerful, Quiet, and Extremely Reliable – Engineered for High-Capacity Volume Reduction of Metal Swarf

The KB20 metal swarf & chip crusher is a high-performance solution designed for higher chip flows in centralized chip handling systems. This robust crusher utilizes low-speed operation to break down long and bushy metal swarf into shorter fragments, making them ideal for centrifuging, briquetting, or further processing. Thanks to an integrated hydraulic tramp metal discharge, solid objects pass through automatically without causing downtime or requiring manual clearing, ensuring exceptional reliability during continuous industrial operation. Swedish-manufactured quality with minimal energy consumption and a noise level below 70 dB(A).

Key Applications

- Large-scale crushing of long and bushy steel chips and swarf

- Volume reduction in centralized chip and fluid handling systems

- Pre-treatment of chips prior to high-capacity centrifuging or briquetting

- Integration into both stand-alone and central chip handling solutions

Benefits

- Very low energy consumption and minimal wear due to low-speed crushing

- Effectively handles large chip nests and varying materials without disruptions

- Hydraulic tramp metal discharge – solid objects pass through safely without damage

- Stable and compact design for easy integration into existing production lines

- Extremely quiet operation (<70 dB(A)) for a better working environment

- Manufactured in Sweden – built for the most demanding industrial applications

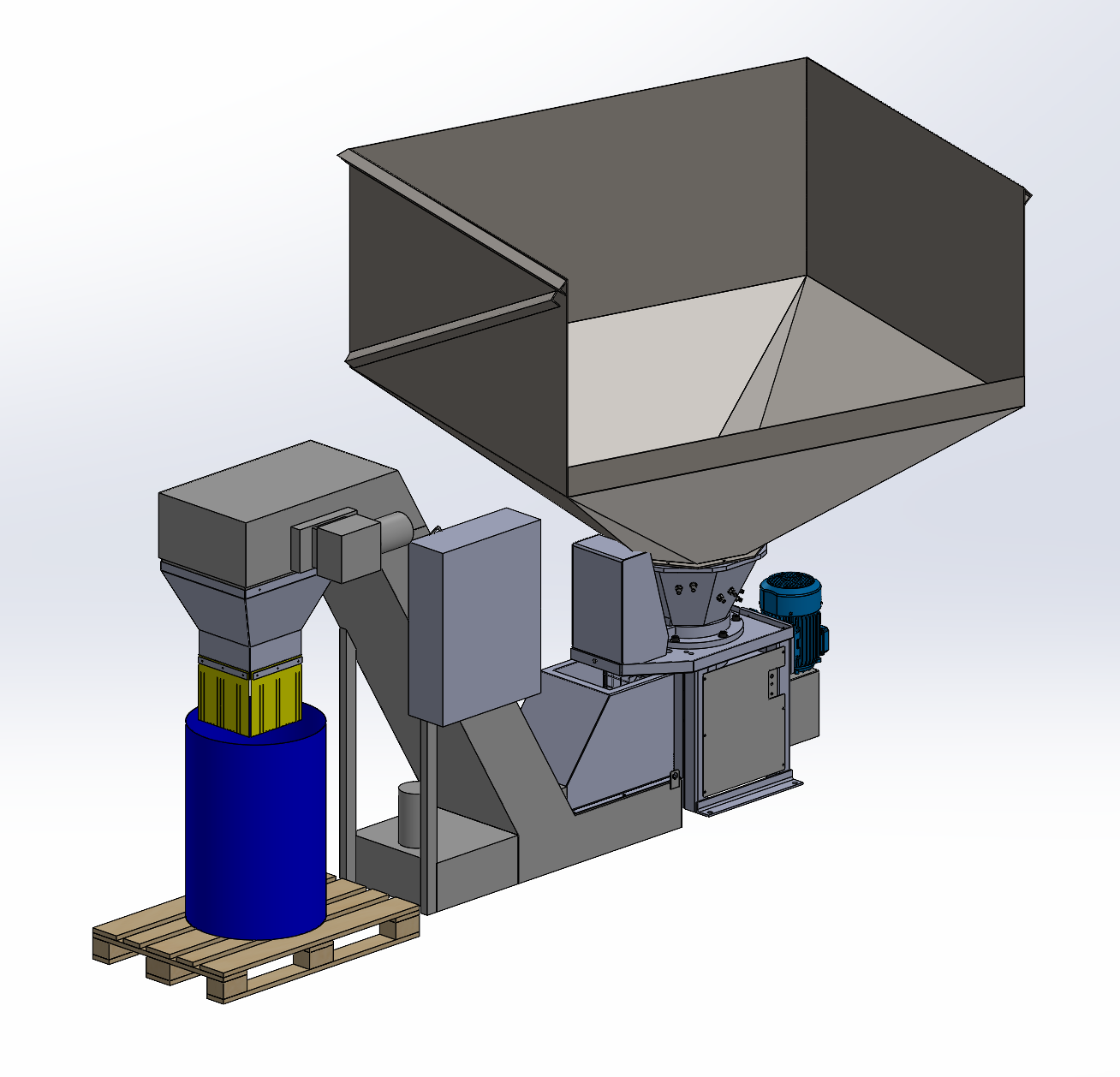

System Integration

The KB20 can be installed as a standalone crusher or integrated into complete chip handling systems together with conveyors, centrifuges, briquetting equipment and fluid separation. The consistent chip size that the KB20 produces creates stable flow and high reliability in subsequent process steps.

Contact Us for Fast Support

Questions or Need Help Finding the Right Solution?

We would be happy to help you and will get back to you shortly. Use the form below, call, or email us for advice, customisations, and quotations.

Call: +46 21 33 80 500 | Email: info@primetek.se

Design

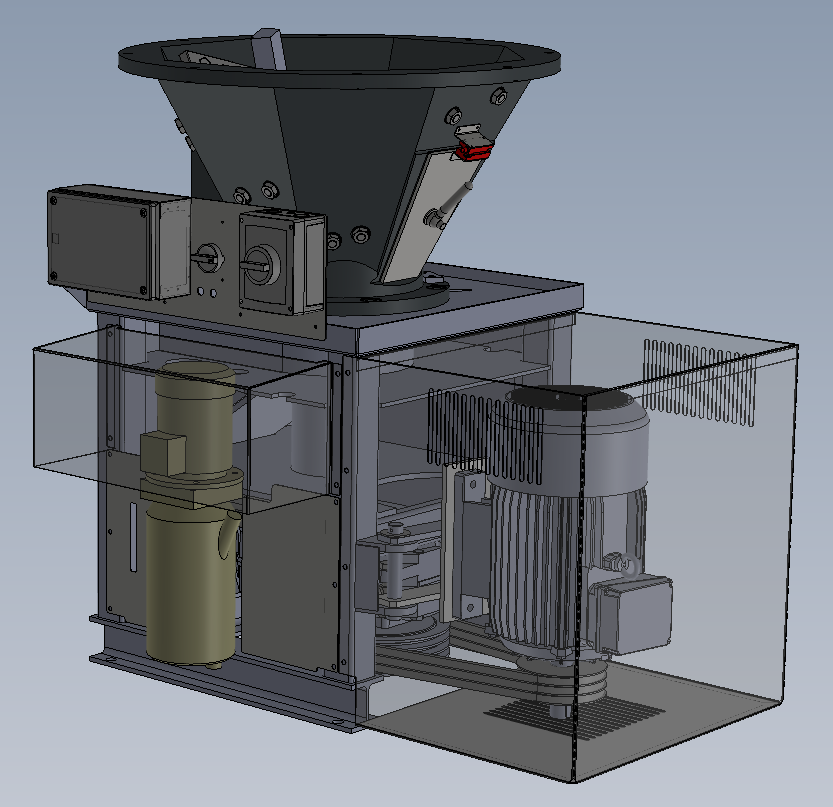

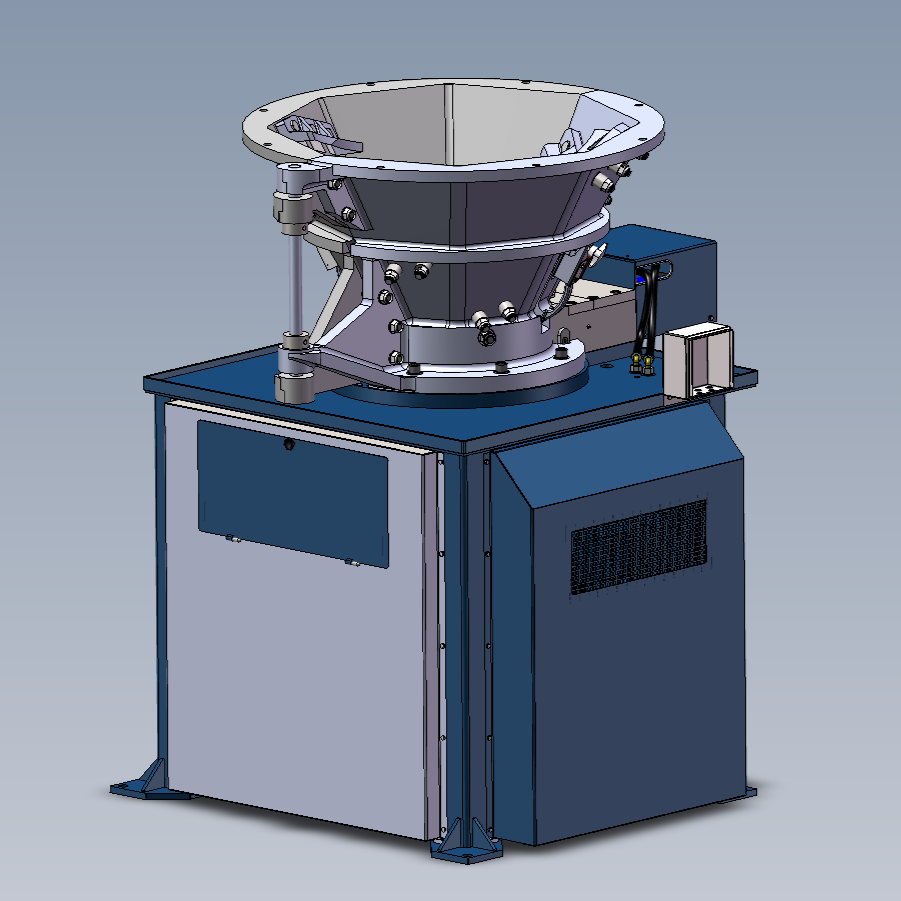

The KB20 is a powerful and low-speed chip crusher with high capacity and a robust design intended for continuous industrial operation. The machine has a spacious conical feed hopper with rotating feed arm that efficiently pulls down bushy and tangled chips to the crushing head, where the material is ground into short chip fragments of uniform size.

A central part of the design is the hydraulic bar end ejection system. Through split tools and automatic reversing, solid objects – such as bar ends and bolts – can pass through the crusher without causing downtime or damage. This provides very high operational reliability, low maintenance and stable function even with large chip nests and varying materials.

Operation

The chips are fed into the hopper and caught by the feed arm, which provides a steady flow into the crushing zone. At the bottom, the crushing head works against the stationary ring and breaks down the material into short chip fragments. The finished fragments then fall directly out through the outlet for further handling, such as centrifuging, briquetting or transport.

The machine continuously monitors its load and automatically reverses with an open bar end ejection if a solid object enters the crusher. In this way, the part can pass without manual cleaning, which ensures stable operation and very low maintenance requirements.

Accessories & Options

- Upper receiving hopper – design, volume and connections according to feeding system

- Stand or mounting if special positioning in system is required

- Level guard in hopper for feed control (optional)

With these options, the KB20 can be integrated effectively into both simple and more advanced chip systems without changing the machine's function or capacity.

Technical Specifications

The KB20 is a robust and low-speed chip crusher designed for high operational reliability and long service life in demanding industrial environments.

Standard data for the KB20 is specified below – the model has fixed performance and design characteristics.

| Footprint | 740x1425mm |

| Capacity (steel & brass) | 800-1000 kg/h |

| Capacity (aluminium) | 250-350 kg/h |

| Weight | Approx. 1200 kg |

| Bar end ejection | Yes, hydraulic |

| Drive motor | 15kW |

Documentation

Download technical documentation and materials for quotations, installation, and service.

Related Products

Disc Crushers (Shredders)

Swarf Crusher KB14

Swarf Crusher KB30

Send Inquiry for Quotation & Technical Support

Submit your requirements. Our team will review your inquiry and contact you shortly regarding technical specifications, customisation, or pricing.

Or Contact Directly:

Phone: +46 21 33 80 500

Email: info@primetek.se

"*" indicates required fields