Swarf Centrifuge VD40

Compact, Vertical Swarf Centrifuge for Efficient Fluid Separation and Automated Chip Transport

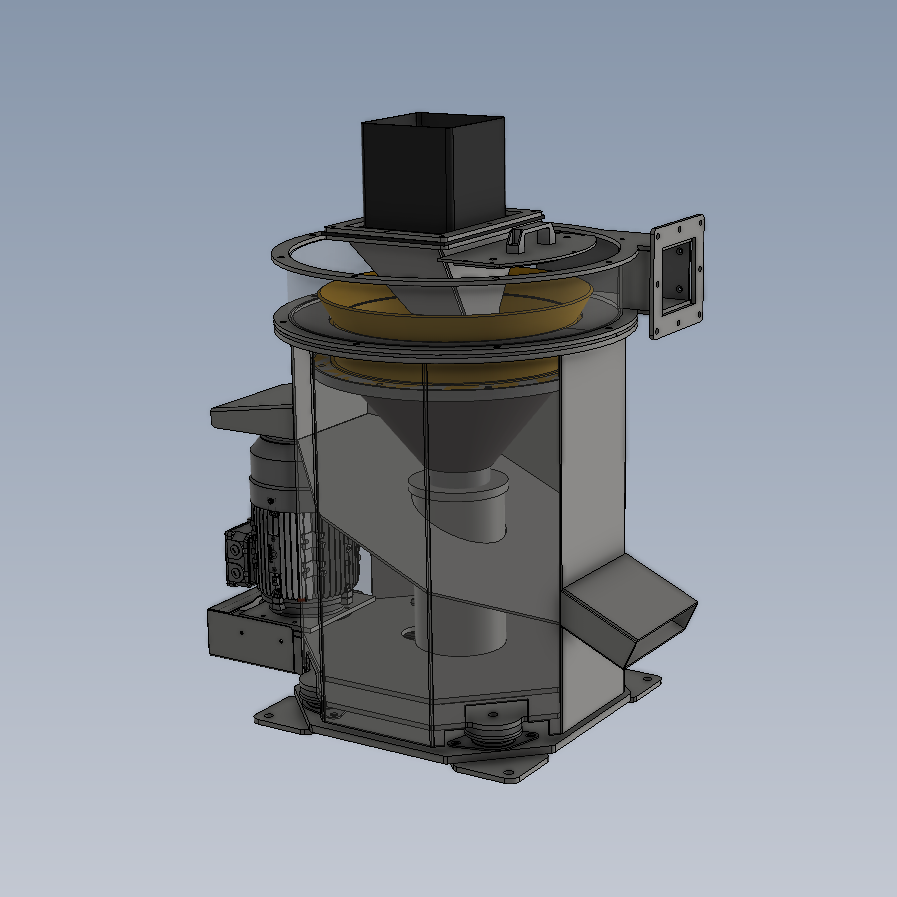

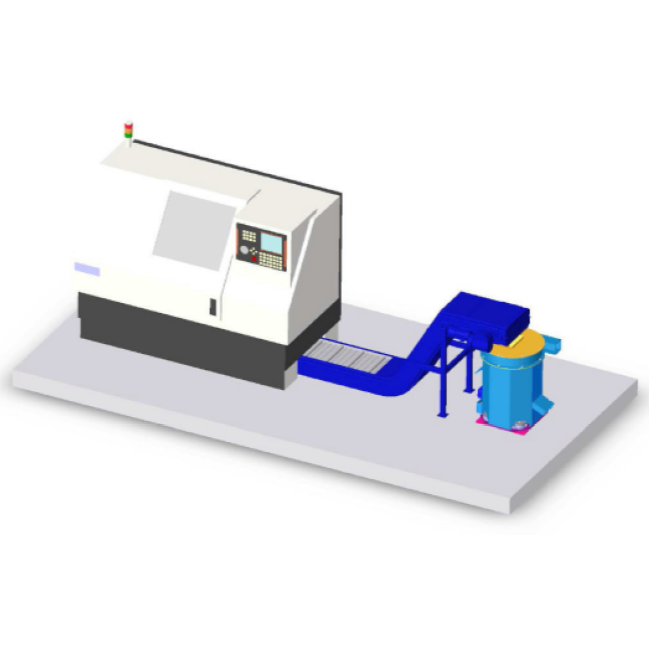

The VD40 metal swarf & chip centrifuge is a compact, vertical solution designed for the dual purpose of centrifuging cutting fluids and providing automatic chip transport in a single system. This centrifuge separates coolant from short metal swarf and utilizes an integrated airflow to convey the dry chips directly to an external container, eliminating the need for a separate discharge conveyor. With a very compact footprint that fits beneath a standard machine conveyor, it delivers exceptional fluid separation with 1–3% residual moisture. Ideal for installation directly at CNC machines and machining centres where both separation and transport are required.

Key Applications

- Separation of cutting fluids from short metal chips and swarf directly after machining

- Automated separation and transport of chips from machining machines and production lines

- Compact swarf handling systems where both fluid separation and transport are required in a single unit

- Installation directly at the machine conveyor – a convenient alternative to traditional chip bins

- Pre-treatment in smaller chip and fluid handling systems

Benefits

- Two functions in one unit – both fluid separation and downstream chip transport

- Very compact design – fits beneath a standard machine conveyor

- Automatically transports chips away from the machine, keeping the work area clean

- Low noise level thanks to vibration-damped design

- Fast and easy service access via inspection hatch

- Delivers chips with very low residual fluid content (1–3%) according to the datasheet

- No separate discharge conveyor required – chips are blown directly to a container

- Manufactured in Sweden – built for demanding industrial applications

System Integration

VD40 can be installed as a standalone centrifuge or integrated into compact chip handling systems together with conveyors, crushers, and fluid recovery systems. The efficient fluid separation results in lower residual fluid in the chips, which both increases material value and reduces cutting fluid consumption. The very compact design makes VD40 particularly well suited for confined spaces and direct installation under machine conveyors.

Contact Us for Fast Support

Questions or Need Help Finding the Right Solution?

We would be happy to help you and will get back to you shortly. Use the form below, call, or email us for advice, customisations, and quotations.

Call: +46 21 33 80 500 | Email: info@primetek.se

Design

VD40 is a compact vertical centrifuge designed to separate fluid from wet metal chips and transport them onwards with a powerful air flow in a single step. The design is based on a vertically positioned drum with a wedge-wire screen (0.7 mm opening as standard) where coolant is efficiently separated and can be returned to production. The robust and vibration-damped design allows the unit to be positioned directly at the machining centre without disturbing the work environment.

The machine is equipped with an inspection hatch providing quick access to the drum for servicing and cleaning. An integrated fan system blows out the dry chip fragments through the discharge pipe to an external container, eliminating the need for a separate conveyor.

Operation

Short, wet chips (max 30 mm) are fed into the centrifuge via a conveyor. The chips reach the drum's centre and are forced upward by centrifugal force. At the drum's periphery is a wedge-wire screen where coolant is pressed through whilst dry chips are ejected through the discharge.

The integrated fan system creates a powerful air stream that can transport the dry chips several metres, depending on height and angle. The result is a very compact complete solution where separation, transport, and fluid recovery occur automatically.

VD40 typically delivers 1–3% residual moisture content at capacities around 100–300 kg/h

Accessories & Options

VD40 is delivered as a complete unit and requires few accessories. The following options can be used to customise the installation:

- Scrap separator before the centrifuge when the feed contains longer chips or solid pieces.

- Custom connection to feeding conveyor depending on machine model

- Stands and support structures can be adapted as required

With these options, VD40 can be integrated effectively into both simple and more advanced chip handling systems without changing the machine's function or capacity.

Technical Specifications

VD40 is a compact centrifuge for efficient fluid separation and air-driven transport of short metal chips. The model has fixed performance characteristics and is particularly suitable for installation directly at machining centres or as part of a compact chip handling system.

| Footprint | 850 x 700 mm |

| Capacity | 100-300 kg/h |

| Residual moisture | 1-3% |

| Noise level | 79.2 dB(A) |

| Drive motor | 4 kW |

Documentation

Download technical documentation and materials for quotations, installation, and service.

Related Products

Hydramax Lift-Bottom Centrifuges

Batch Centrifuges MZ

Send Inquiry for Quotation & Technical Support

Submit your requirements. Our team will review your inquiry and contact you shortly regarding technical specifications, customisation, or pricing.

Or Contact Directly:

Phone: +46 21 33 80 500

Email: info@primetek.se

"*" indicates required fields