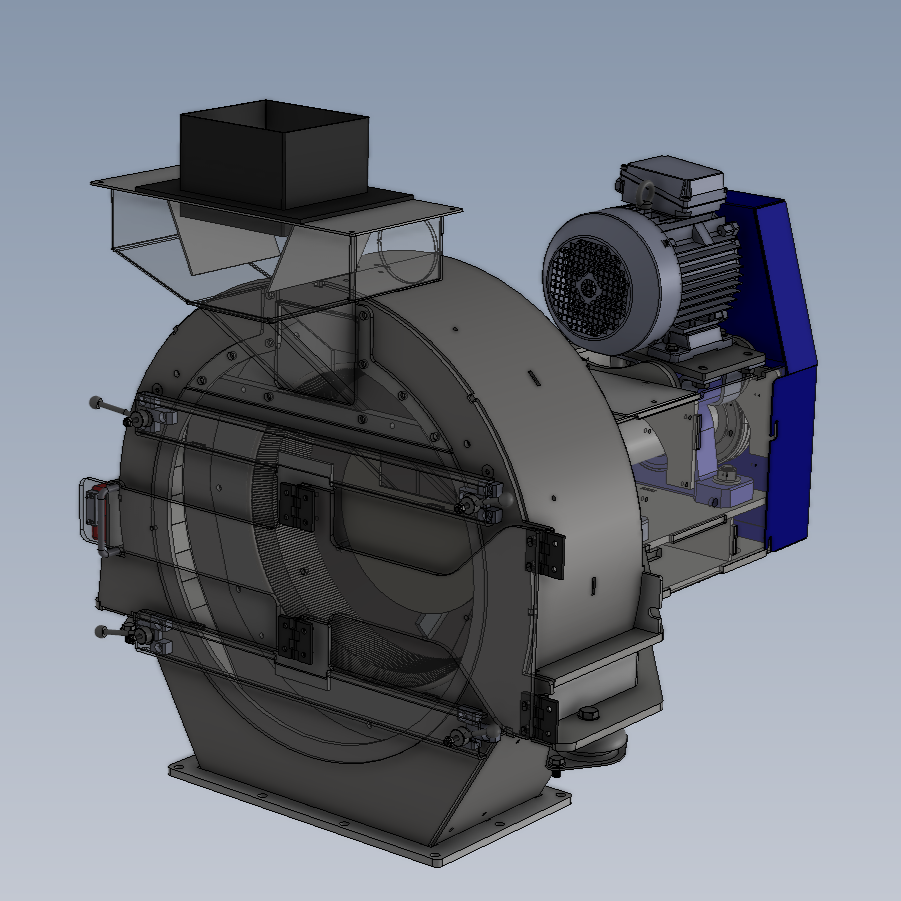

Swarf Centrifuge HD50

Horizontal Swarf Centrifuge for Efficient Separation of Cutting Fluid During Continuous Feed

The HD50 metal swarf & chip centrifuge is a horizontal solution designed for efficient centrifuging of cutting fluid from short metal chips under continuous feed in automated chip handling systems. This robust centrifuge features a wedge bar screen and automatic discharge, separating coolant with a residual moisture content of 2–5% and a capacity of up to 600 kg/h. With its horizontal design and all components easily accessible, the HD50 offers very short service times and high operational reliability in continuous-flow applications. The compact design handles all chip types shorter than 30 mm without manual intervention.

Key Applications

- Separation of cutting fluid from short metal chips and swarf in continuous production systems

- Pre-treatment of chips and swarf prior to further processing or briquetting

- Installation in central chip handling systems where high operational reliability is critical

- Applications requiring fast cleaning and minimal downtime during material changes

Benefits

- Horizontal design delivers very low operating and maintenance costs

- Fast cleaning – the drum can be cleaned in under 10 minutes

- Automatic discharge after each cycle ensures clean operation and enables processing of multiple materials in sequence

- Handles all chip types shorter than 30 mm without manual service

- Robust design suitable for continuous flow in automated systems

- All components are easily accessible for service

- Quiet and stable operation thanks to balanced components

- Manufactured in Sweden – built for demanding industrial environments

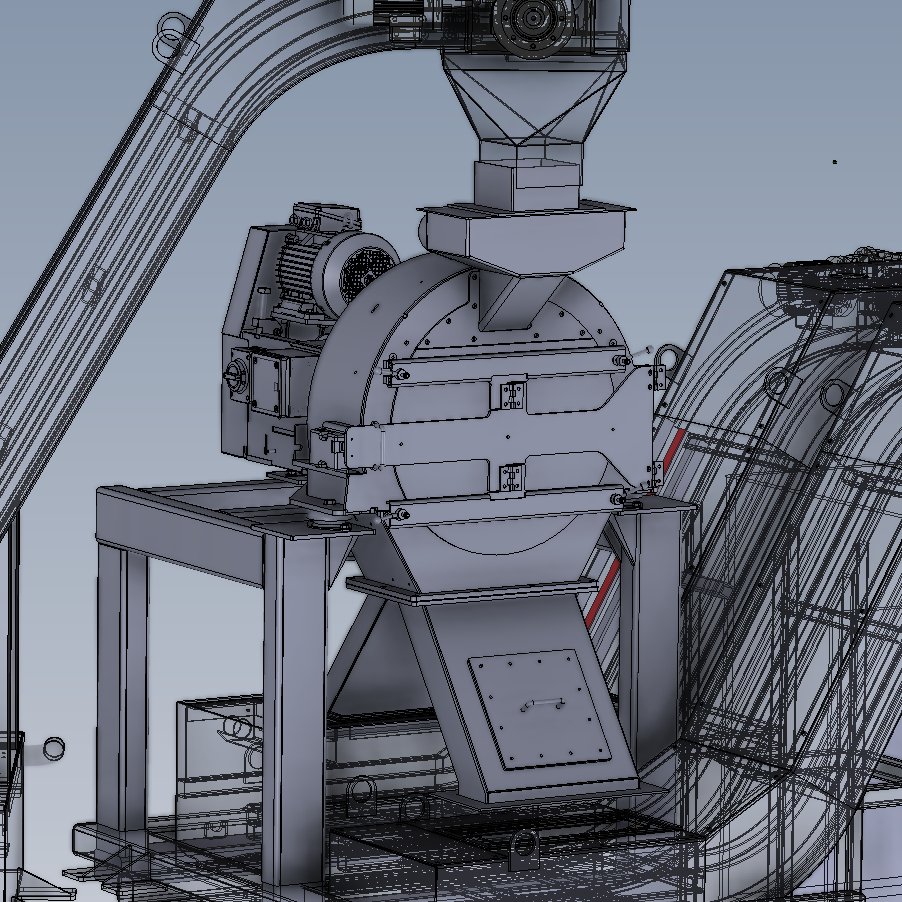

System Integration

HD50 can be installed as a standalone centrifuge or integrated into central chip handling systems together with conveyors, crushers, briquetting equipment, and fluid recovery systems. The horizontal design and automatic discharge make the centrifuge very well suited for continuous flows where high reliability is critical.

The efficient fluid separation results in lower residual fluid in the chips, which increases material value and reduces cutting fluid consumption in subsequent processes. Thanks to its compact and service-friendly design, HD50 is easy to integrate into both new and existing system solutions.

Contact Us for Fast Support

Questions or Need Help Finding the Right Solution?

We would be happy to help you and will get back to you shortly. Use the form below, call, or email us for advice, customisations, and quotations.

Call: +46 21 33 80 500 | Email: info@primetek.se

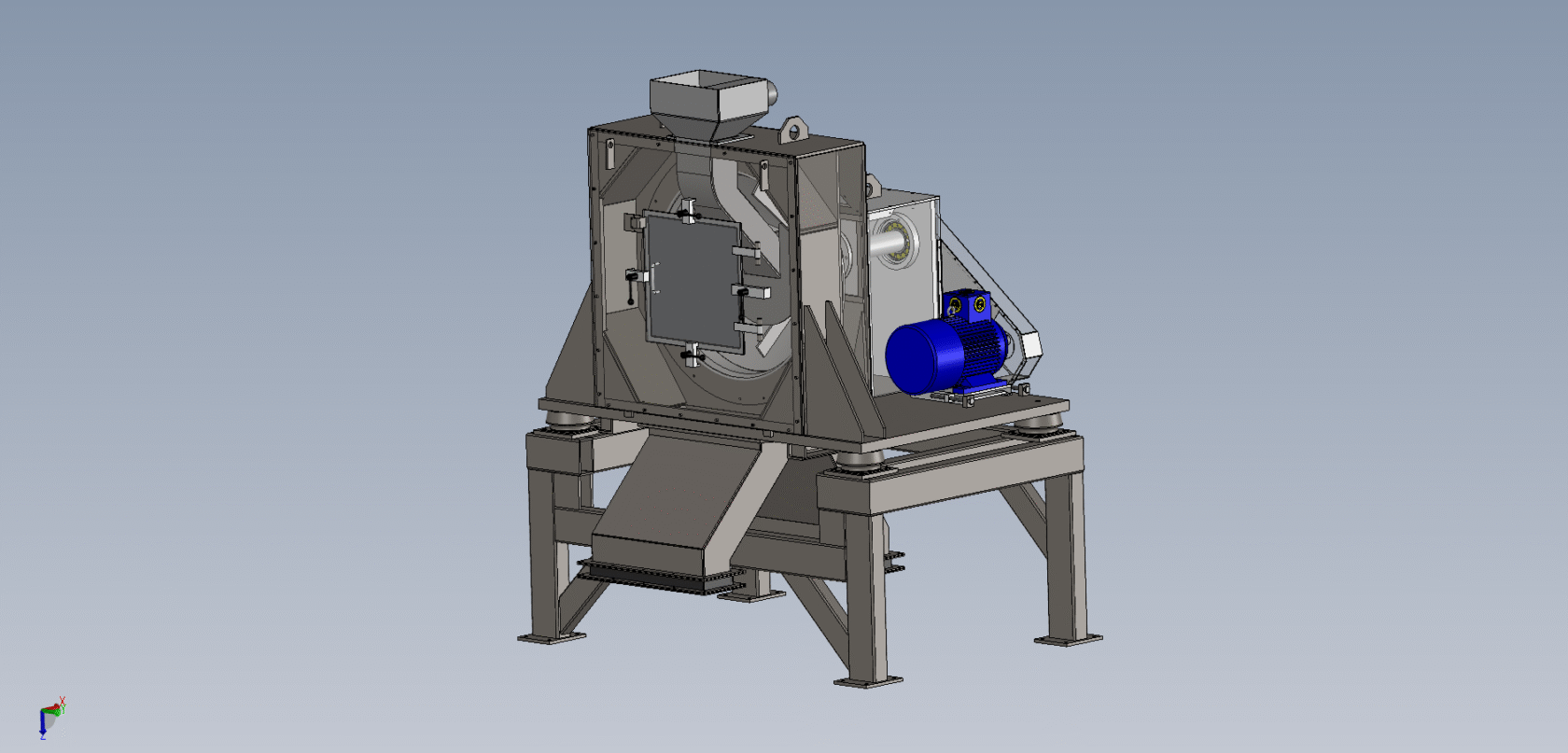

Design

HD50 is a compact horizontal centrifuge with a rotating drum suspended in a stable frame. Inside the drum is a wedge-wire screen (0.7 mm opening as standard) that separates cutting fluid from chips at high rotational speed. The horizontal design makes all components easily accessible and significantly reduces servicing and cleaning time.

The automatic discharge function ensures the drum empties completely of chips and fluid after each operating cycle. This makes HD50 ideal in systems handling multiple different metals or material types in sequence, as well as in installations requiring high cleanliness standards and minimal maintenance.

Operation

Short and wet chips (<30 mm) are fed via a conveyor into the centrifuge's receiving hopper where a chute directs the chips into the drum's centre. At high rotational speed, fluid is pressed through the wedge-wire screen whilst dry chips are conveyed onwards to the discharge point at the front of the machine. The horizontal design enables the drum to empty completely automatically—even after stops—which minimises spillage and ensures a clean process.

HD50 delivers a residual moisture content of 2–5%, depending on chip density and coolant properties.

Accessories & Options

HD50 is delivered as a complete unit and requires few accessories. The following options can be used to customise the installation:

- Scrap separator before the centrifuge when the feed contains longer chips or solid pieces.

- Custom connection to feeding conveyor depending on machine model

- Stands and support structures can be adapted as required

With these options, HD50 can be integrated effectively into both simple and more advanced chip handling systems without changing the machine's function or capacity.

Technical Specifications

HD50 is a horizontal centrifuge for efficient separation of cutting fluid from short metal chips with continuous feed. The model has fixed performance characteristics and is particularly suitable for installation in central chip handling systems or as part of automated processes with high demands for reliability and rapid cleaning.

| Footprint | 1,300 x 1,500 mm |

| Capacity | <600 kg/h |

| Residual moisture | 2-5% |

| Noise level | 79.2 dB(A) |

| Drive motor | 4 kW |

Documentation

Download technical documentation and materials for quotations, installation, and service.

Related Products

Swarf Centrifuge HD82

Swarf Centrifuge HD100

Send Inquiry for Quotation & Technical Support

Submit your requirements. Our team will review your inquiry and contact you shortly regarding technical specifications, customisation, or pricing.

Or Contact Directly:

Phone: +46 21 33 80 500

Email: info@primetek.se

"*" indicates required fields