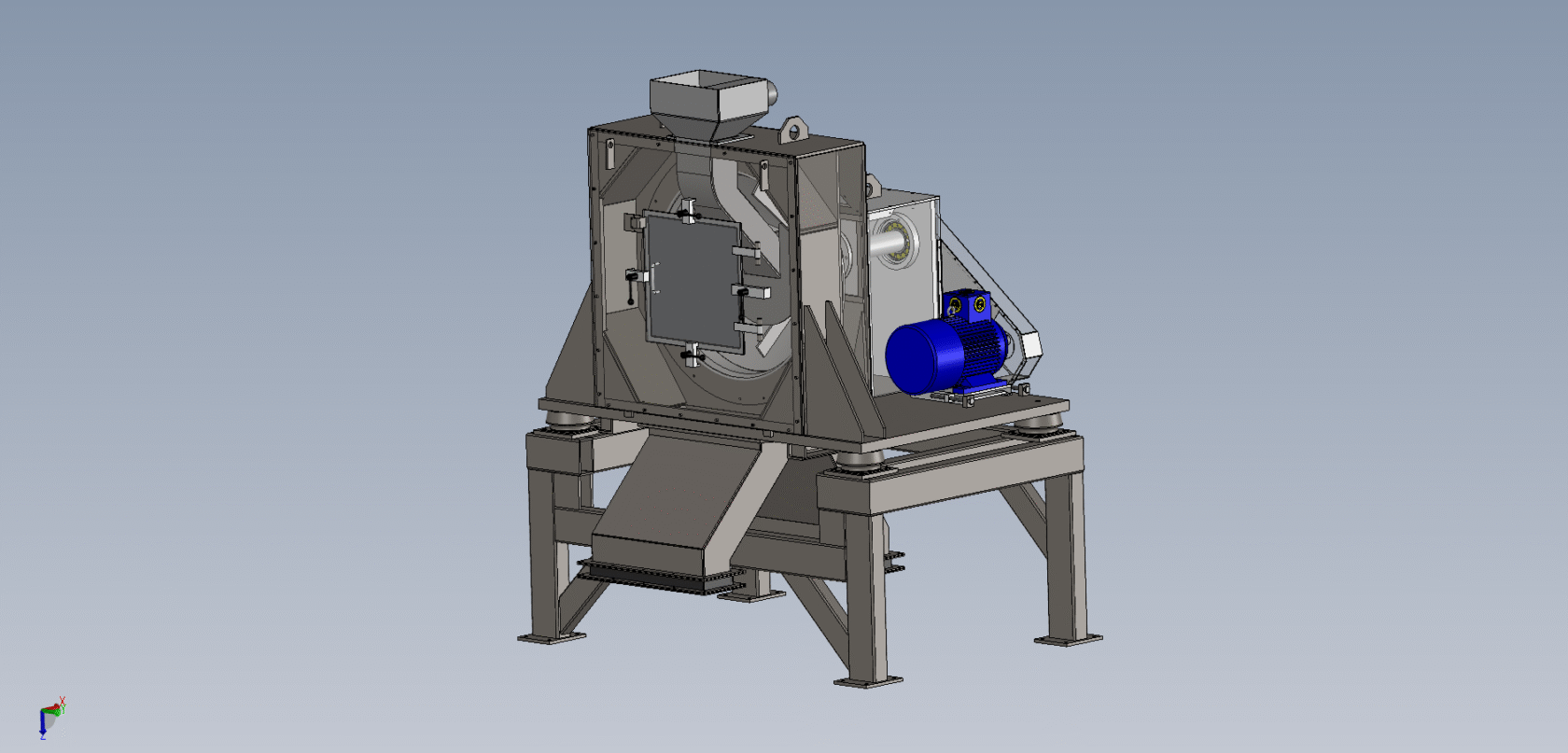

Hydramax Lift-Bottom Centrifuges

Maximised Fluid Separation and Stable Operation When Handling Large Quantities of Chips and Grinding Dust

The Hydramax series consists of robust chip centrifuges with a hydraulic lifting bottom, designed for efficient centrifuging of cutting fluid from large volumes of short chips, grinding dust and sludge in linear or centralized chip handling systems. These powerful centrifuges feature a hydraulic lifting bottom and a slotted screen, delivering very high oil separation efficiency and automatic coolant separation during continuous operation. With capacities ranging from 750 kg/h (Hydramax 4) up to 4,500 kg/h (Hydramax 6) for grey cast iron, the series is suitable for both medium and large chip flows. Fully automatic operation with very low maintenance requirements and a compact design.

Key Applications

- Linear or centralised chip systems

- For short chips, grinding dust and sludge

- High flows of short metal chips (steel, cast iron, aluminium, etc.)

- Systems where continuous operation and low operator input are critical

Benefits

- Wear-resistant, robust design

- Suitable for both grinding dust and short chips

- Very high separation efficiency for oil

- Fully automatic operation

- Compact design – easy to integrate

- Very low maintenance requirements

- Service-friendly construction

Technical Overview – Hydramax

| Model | Drum Diameter | Power | Capacity (Steel) | Capacity (Aluminium) | Capacity (Cast Iron) |

| Hydramax 4 | 400 mm | 3.0 kW | 750 kg/h | 300 kg/h | 1100 kg/h |

| Hydramax 5 | 500 mm | 4.0 kW | 1500 kg/h | 550 kg/h | 2200 kg/h |

| Hydramax 6 | 600 mm | 5.5 kW | 3000 kg/h | 1000 kg/h | 4500 kg/h |

Capacity depends on the chip shape, length and density.

Contact Us for Fast Support

Questions or Need Help Finding the Right Solution?

We would be happy to help you and will get back to you shortly. Use the form below, call, or email us for advice, customisations, and quotations.

Call: +46 21 33 80 500 | Email: info@primetek.se

System Integration

These centrifuges are easy to integrate into centralised chip systems with feed hoppers, conveyors and complementary fluid purification.

Operation

- Fully automatic fluid separation of large quantities of metal chips and grinding masses

- Lift bottom with hydraulics for stable and continuous discharge

- Slotted screen for efficient fluid separation

- Robust drum for demanding industrial operation

- Energy-efficient drive with optimised power class

Related products

Swarf Centrifuge HD100

Send Inquiry for Quotation & Technical Support

Submit your requirements. Our team will review your inquiry and contact you shortly regarding technical specifications, customisation, or pricing.

Or Contact Directly:

Phone: +46 21 33 80 500

Email: info@primetek.se

"*" indicates required fields