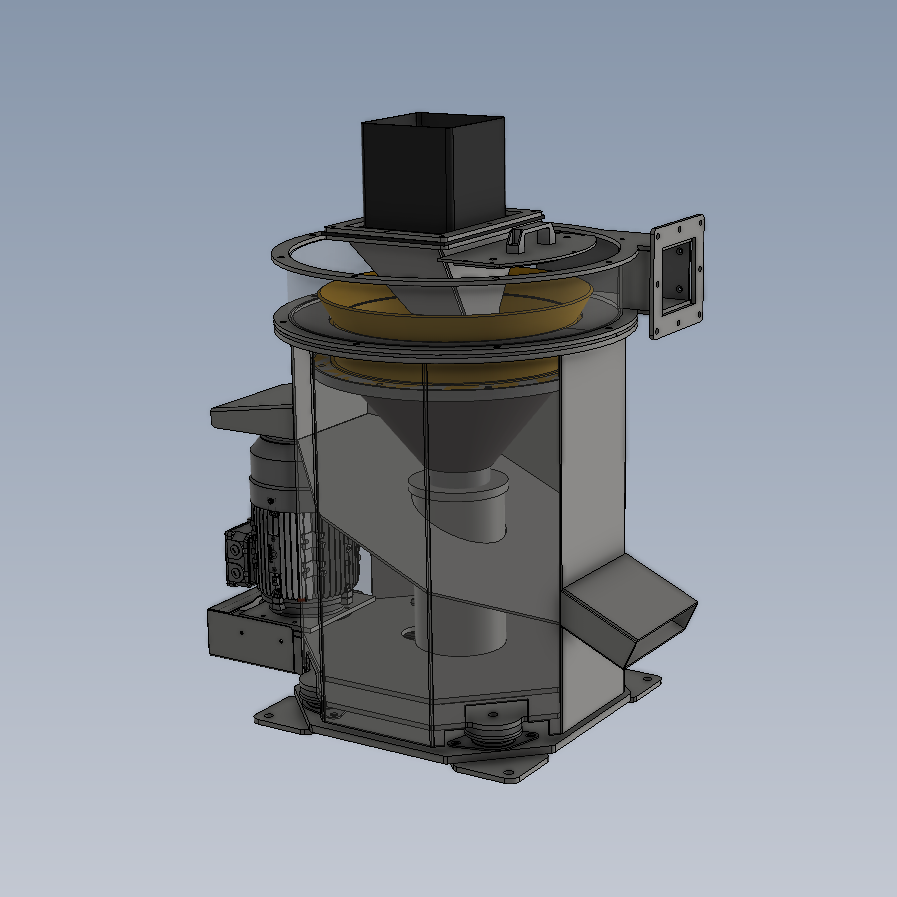

Disc Crushers (Shredders)

Efficient Breakdown of Chips & Residual Materials

Disc crushers are robust chip crushers designed to break down long, tangled and bushy metal chips into shorter, free-flowing fragments. These powerful crushers, equipped with single-shaft or double-shaft cutting discs, are used upstream of centrifuging, briquetting or conveying to create a uniform material flow and reduce the volume of chips from CNC machines and machining centres. With a modular design, adjustable cutting geometry and a wide range of sizes, disc crushers are suitable for both small and large chip flows. Available in a wide range of capacities from 100 kg/h up to more than 3,000 kg/h, depending on material and application.

Key Applications

- Breakdown of long, tangled or bushy metal chips before transport, centrifuging or briquetting

- Distribution of residual materials and solid metal fragments to pumpable or transportable size

- Pre-treatment in chip systems where chips must be shortened and homogenised

- Applications where uneven material flow requires robust and reliable crushing

- Integration into automatic chip handling systems with high demands on uniform granulation

Benefits

- Modular system – large number of sizes and designs

- Single-shaft and double-shaft models depending on capacity requirements and material type

- Uniform granulation thanks to cutting discs and adjustable cutting geometry

- Can be integrated into both small and large systems, before centrifuges, pumps or briquetting presses

- Robust industrial design for long service life and low service costs

Technical Overview – Disc Crushers

| Model | Type | Capacity steel (kg/h) | Capacity aluminium (kg/h) | Power |

Opening (mm) |

| EZ 6 | Single-shaft | 100 | 80 | 3.0 kW | 620 x 320 |

| ZW 400 | Double-shaft | 100 | 75 | 3-4 kW | 330 x 400 |

| ZW 500 / 500 M | Double-shaft | 400 | 250 | 5.5-7.5 kW | 440 x 580 |

| ZW 800 | Double-shaft | 1000 | 600 | 2 x 5.5-7.5 kW | 830 x 580 |

| ZW 900 | Double-shaft | 2000 | 1500 | 15 kW | 890 x 750 |

This is a selection of our most common disc crushers.

The programme comprises a large number of models from small single-shaft crushers to powerful double-shaft units with capacities exceeding 3,000 kg/h.

We are happy to help you select the right model based on chip type, flow rate, feeding method and granulation requirements.

Contact Us for Fast Support

Questions or Need Help Finding the Right Solution?

We would be happy to help you and will get back to you shortly. Use the form below, call, or email us for advice, customisations, and quotations.

Call: +46 21 33 80 500 | Email: info@primetek.se

System Integration

The disc crushers can be used standalone or integrated as pre-crushers in complete chip handling systems together with conveyors, centrifuges and briquetting equipment. By shortening and homogenising the chips already at the inlet, a stable material flow and higher operational reliability are created in subsequent process steps.

With options such as bar end ejection, friction clutch and automatic start/stop, the crushers can be easily adapted to both small and advanced system solutions.

Operation

The material is fed into the crusher opening and guided down towards the rotating discs where the chips are cut, torn or sheared down into shorter and more free-flowing fragments. Single-shaft models work against a static shear bar, whilst double-shaft models use two counter-rotating shafts to efficiently draw in, break down and distribute even tangled or bushy chips.

The finished material leaves the crusher in a uniform and controlled size that is easy to transport onwards to centrifuging, briquetting or fluid separation. Options such as friction clutch or bar end ejection protect the machine against solid objects and contribute to high operational reliability even with varying material flows.

Accessories & Options

The disc crushers are available in a modular design and can be equipped with several options depending on material and system solution:

- Bar end ejection for safe passage of solid objects (Applies to certain models)

- Friction clutch to protect the cutting mechanism and extend service life (Applies to certain models)

- Fill level sensor for automatic start/stop and energy-efficient operation

- Special hoppers and feeding solutions for tangled or voluminous chips

- Integrated stands and frames for adapted height or connection to conveyor

- Replaceable cutting discs and counter knives in various geometries

- Custom-made guards and enclosures for safety and noise reduction

These options make it possible to adapt the crusher to both small and advanced chip systems without affecting the machine's basic function.

Related products

Swarf Centrifuge VD40

Swarf Centrifuge HD50

Swarf Centrifuge HD82

Send Inquiry for Quotation & Technical Support

Submit your requirements. Our team will review your inquiry and contact you shortly regarding technical specifications, customisation, or pricing.

Or Contact Directly:

Phone: +46 21 33 80 500

Email: info@primetek.se

"*" indicates required fields