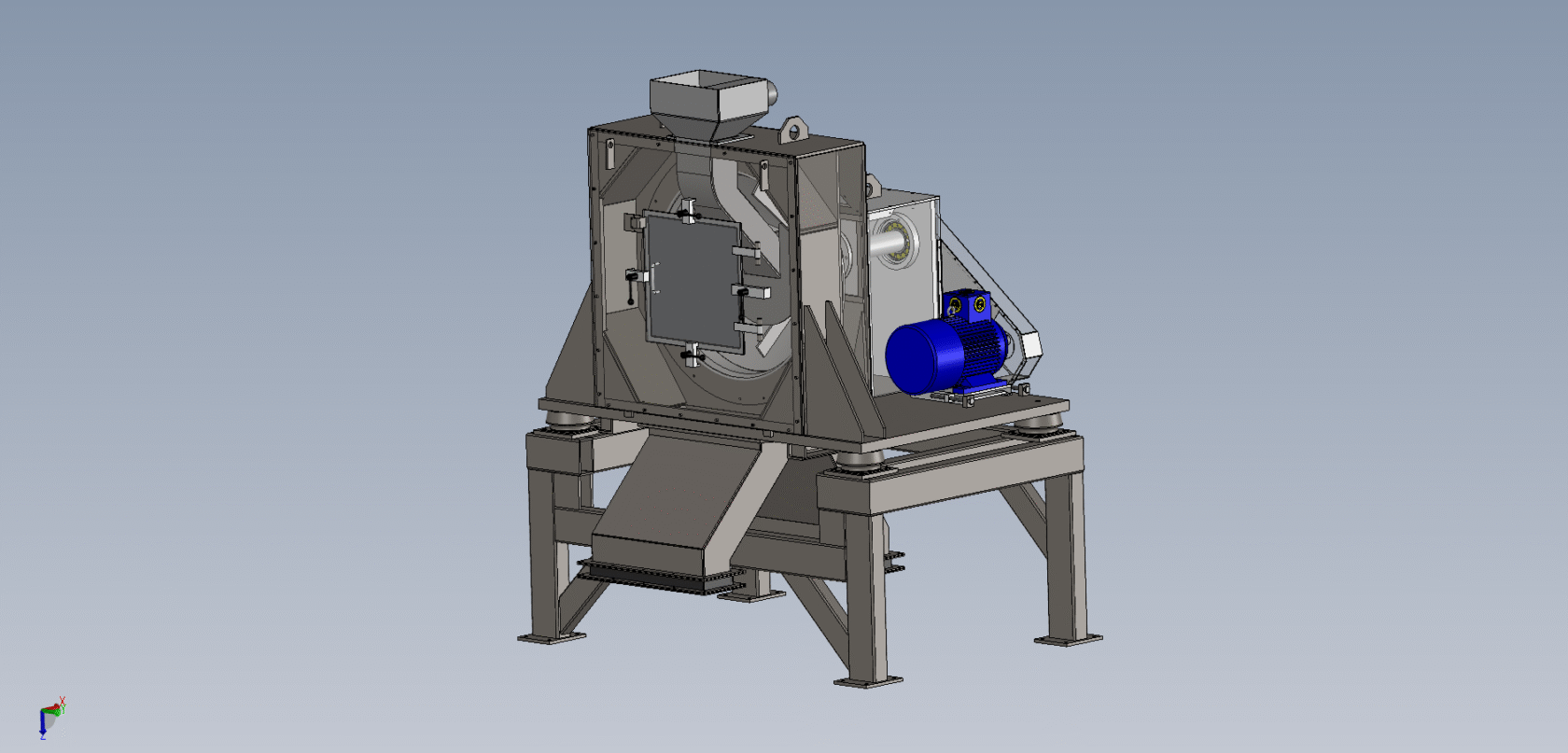

Batch Centrifuges MZ

Flexible Fluid Separation and Drying for Lower Flow Rates and Varied Materials

The MZ series consists of flexible batch centrifuges designed for efficient centrifuging of cutting fluid and drying of smaller quantities of metal chips in batch operation. These chip centrifuges handle long, bushy or mixed chips that are difficult for continuous centrifuges and are ideally suited for production involving multiple material types processed in sequence. With models ranging from MZ 300 (15 litres) up to MZ 600 (100 litres), as well as the special MZ-L series for lightweight materials, the range offers high flexibility at a low investment cost. A wide range of accessories is available, including lifting crane, washing unit and variable frequency drive, supporting both manual and semi-automatic workflows.

Key Applications

- Fluid separation and drying of smaller quantities of metal chips

- Handling of long, bushy or mixed chips where continuous centrifuges do not work

- Production where many material types are run in sequence

- Applications where low investment cost and high flexibility are important

- Installation as a standalone station or in small chip systems

Benefits

- Very flexible use – can be moved and used where the need arises

- Cost-effective alternative for low chip volumes

- Handles long and bushy chips that are difficult to process continuously

- Wide range of accessories: lifting crane, washing unit, heating, frequency control, special drums, etc.

- Available in several sizes: MZ 300–600 and MZ 500L–700L for light chips

Technical Overview – MZ Series

Standard Models

| Model | Drum Diameter | Drum Height | Max Load | Volume | Speed | Capacity (batches/h) |

| MZ 300 | 300 mm | 250 mm | 35 kg | 15 l | 1500 rpm | 10 |

| MZ 400 | 400 mm | 300 mm | 50 kg | 40l | 1200 rpm | 8-10 |

| MZ 500 | 500 mm | 350 mm | 100 kg | 70 l | 1000 rpm | 8-10 |

| MZ 600 | 600 mm | 350 mm | 150 kg | 100 l | 750 rpm | 8 |

L-series for lighter chips (Al/Ti)

| Model | Drum Diameter | Drum Height | Max Load | Volume | Speed | Capacity (batches/h) |

| MZ 500L | 500 mm | 350 mm | 50 kg | 50 l | 1000 | 8-10 |

| MZ 600L | 600 mm | 350 mm | 65 kg | 65 l | 750 | 8-10 |

| MZ 700L | 700 mm | 380 mm | 65 kg | 90 l | 750 | 8 |

Capacity depends on the chip shape, length and density.

Contact Us for Fast Support

Questions or Need Help Finding the Right Solution?

We would be happy to help you and will get back to you shortly. Use the form below, call, or email us for advice, customisations, and quotations.

Call: +46 21 33 80 500 | Email: info@primetek.se

System Integration

Batch centrifuges in the MZ series can be used as standalone stations or integrated into smaller chip handling systems. They are particularly suitable in operations with multiple material types, varying flow rates or need for flexible positioning. Through their wide range of accessories, they can be adapted to both manual and semi-automatic workflows.

Operation

Chips or parts are placed in the centrifuge drum and positioned manually or with a lifting device. When the lid is locked, the centrifuge starts and the drum accelerates up to the selected speed. During rotation, the cutting fluid is pressed through the drum's perforations whilst the material is retained in the drum.

When the centrifuging cycle is complete, the drum is braked and can be emptied manually or with the help of accessories such as a swing crane, hoist or transport trolley. The batch process makes it easy to handle different materials, different chip shapes or separate parts without risk of mixing, whilst achieving low residual fluid.

Accessories

- Swing crane or chain hoist for drum handling

- Gripping devices for drums and containers

- Frequency control / speed regulation

- Washing / rinsing unit

- Transport trolleys for drums

- PLC control / automation solutions

- Customer-specific mountings and stands

Documentation

Download technical documentation and materials for quotations, installation, and service.

Related products

Swarf Centrifuge HD100

Send Inquiry for Quotation & Technical Support

Submit your requirements. Our team will review your inquiry and contact you shortly regarding technical specifications, customisation, or pricing.

Or Contact Directly:

Phone: +46 21 33 80 500

Email: info@primetek.se

"*" indicates required fields